Total Productive Maintenance - TPM

April 08, 2022

The ultimate objective with TPM (Total Productive Maintenance) is to achieve, via proactive and preventive maintenance, 100% reliability – zero production stops, zero downtime and zero defects. Understand more in this article by our Product and Innovation Manager, Stenio Dias, how this concept is applied in practice.

The idea of Total Productive Maintenance (TPM) emerged in Japan in mid-1971 as a proposal by Seiichi Nakajima to evolve the concept of Preventive Maintenance for a greater contribution to the Production System as a whole from the focus on Equipment Efficiency.

At this time (1945 - 1970) the Japanese, in post-war recovery, found themselves forced to meet all their domestic market demands as a result of severe international embargoes and scarcity of resources, having no other option but to adapt Management and Quality theories and concepts, widespread in the USA, due to its reality of low volumes, high diversity and product mix and low production capacity compared to the market.

The Toyota Production System (STP) or Lean Manufacturing, came as a precursor to this change and the concept of Just in Time (JIT) opened a new horizon in the organization of the Supply Chain bringing Effectiveness as a basis for systemic thinking.

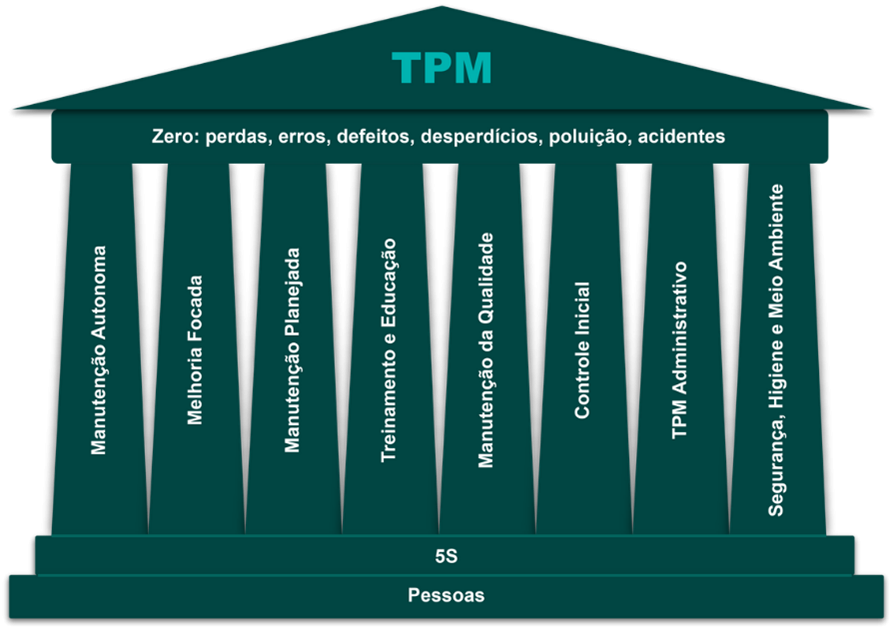

Within this atmosphere of Zero Waste, TPM emerged as a natural evolution of the Effective Production System theme. Among all the STP techniques, Just in Time and 5Ss are the disciplines that contributed most to defining the pillars of TPM.

With a focus on Efficiency through Safety, Reducing Losses, Optimizing Resources, Increasing Productivity and Quality Assurance, in addition to being based on the 5Ss, TPM generates a sense of responsibility throughout the team, from operators, up to senior management, and it is up to business managers to be examples of the cultural change that Lean Manufacturing requires.

What are they:

Seeks the integration and collaboration of Operators in the daily Maintenance routine, giving them autonomy to carry out preventive tasks on their work equipment, such as:

• Cleaning

• Lubrication

• Inspections

This preventive work, as long as it is well recorded and analyzed, allows trends and failures to be identified in time to avoid an unplanned stoppage.

It is the pillar of Continuous Improvement that uses data and maintenance history to define actions to improve Equipment Performance and Performance.

To achieve this, it is essential that there is a culture that systematically seeks the evolution of Processes with a focus on increasing Efficiency. Approaches like Kaizen are very effective.

Prevention is better and cheaper than correction! This is the basis of the Maintenance Planning concept. Preventive and Corrective Maintenance were the main types of maintenance at that time and today we have Predictive, Prescriptive and Planned Corrective as an evolution of the tools and technologies that permeate maintenance.

Regardless of the different types of Planned Maintenance that exist or may come to exist, the idea of Prevention remains intact: Guaranteeing the Organization's Results through the Availability of Equipment.

Currently there are excellent Maintenance Management and Planning tools that enable greater strategic results for the Maintenance area.

Sequor MTC (https://sequormtc.com.br/) is the best solution on the market for Planning, Management and Performing Maintenance.

As with all Lean philosophy, TPM also practices people development and discipline as the foundation for success. People are the basis of any business, whether as a Customer or Supplier, and keeping them motivated, involved and engaged is essential for the processes to function fully.

It is the Total Quality approach within the scope of Maintenance, applying tools for problem solving and continuous improvement such as MASP, PDCA, Ishikawa… allows the reduction of errors, failures and waste. In addition to eliminating waste, reducing the variability of mapped parameters that have a direct impact on equipment availability is essential and this is where Six Sigma tools come in.

Integrated action between Maintenance and Industrial Engineering is very important to start Maintenance planning while still in the equipment design phase. The knowledge base already acquired by the TPM is a source for the Initial Control of new equipment.

Failure Mode and Effect Analysis (FMEA) is an excellent example of how to apply Initial Control to new equipment.

It consists of applying all the concepts of Lean Manufacturing and TPM in the administrative sphere. Applying concepts to eliminate waste, engagement, quality and efficiency.

The concepts of Agile Management have a strong connection with this pillar.

Safety first is a pillar of TPM. Maintenance plans must start with Preliminary Risk Analysis, Work Permit and Work Release, to ensure that everyone involved is safe with risks mapped and mitigated.

Analysis of Environmental Aspects and Impacts generates awareness and concern for the environment during maintenance work, from acquisition to disposal and disposal of inputs and their waste.

A healthy and comfortable work environment increases employee productivity, well-being and engagement.

Check out more at:

https://www.sequor.com.br/br/sequor-mtc

https://sequor.com.br/br/mtc-o -sequor-maintenance-software

https://sequor.com.br/br/processo-de-manutencao-como-fomentar-o-alto-desempenho-na-gestao-e-execucao

This site informs: we use cookies to customize ads and improve your site experience. By continuing to browse, you agree with our Privacy Policy..

continue and close